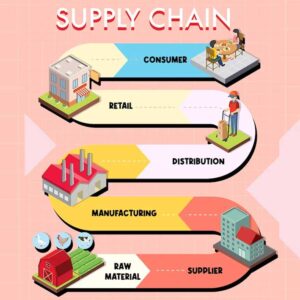

The global business landscape has been increasingly impacted by supply chain disruptions, posing significant challenges for organizations worldwide. From natural disasters and geopolitical tensions to the recent COVID-19 pandemic, disruptions have highlighted the vulnerability of supply chains. In this blog, we will explore the key factors contributing to supply chain disruptions and delve into effective strategies to build resilience and mitigate the impact of disruptions.

- Understanding Supply Chain Disruptions:

Supply chain disruptions can arise from various sources such as natural disasters, supplier bankruptcy, transportation delays, trade wars, or unforeseen events like the COVID-19 pandemic. These disruptions can result in inventory shortages, production delays, increased costs, and damaged customer relationships. - Factors Contributing to Disruptions:

a. Globalization: Increased reliance on global suppliers and complex networks make supply chains susceptible to disruptions across borders.

b. Lack of Transparency: Insufficient visibility into supplier operations and limited information sharing hinders proactive risk management.

c. Single Sourcing: Overreliance on a single supplier or geographic region exposes supply chains to significant risks. - Building Resilience Strategies:

a. Diversification of Suppliers: Engaging multiple suppliers reduces dependency on a single source and mitigates the impact of disruptions.

b. Enhanced Visibility and Transparency: Leveraging technology and data analytics provides real-time visibility into the supply chain, enabling proactive identification and mitigation of risks.

c. Strengthening Supplier Relationships: Collaborating closely with suppliers and fostering transparent communication facilitates early risk detection and joint problem-solving.

d. Robust Risk Assessment and Contingency Planning: Conducting regular risk assessments, developing contingency plans, and creating agile response mechanisms enhances the ability to navigate disruptions effectively.

e. Supply Chain Redesign: Reevaluating the supply chain structure to optimize inventory management, streamline logistics, and identify alternative sourcing options enhances resilience.

Case Studies:

- Toyota’s Resilience Strategy: Toyota’s “just-in-time” production system faced challenges during the 2011 earthquake and tsunami in Japan. The company responded by diversifying suppliers, implementing risk management systems, and creating redundant production capabilities to enhance resilience.

- Apple’s Supplier Collaboration: Apple collaborates closely with its suppliers, providing support, training, and sharing best practices. This collaboration fosters mutual trust and enables timely identification and resolution of potential disruptions.

Quotes:

- “Building a resilient supply chain requires proactive risk management, collaboration, and a focus on long-term sustainability.” – Supply Chain Dive

- “Resilient supply chains are agile, transparent, and capable of rapidly adapting to disruptions.” – McKinsey & Company

Summary:

Supply chain disruptions are inevitable, but organizations can mitigate their impact through proactive resilience strategies. By diversifying suppliers, enhancing visibility, strengthening relationships, and implementing contingency plans, businesses can build resilient supply chains capable of navigating disruptions effectively. Embracing a holistic approach to risk management and adopting innovative technologies will be critical in ensuring long-term sustainability and competitiveness in an increasingly uncertain business environment.

References:

a. Supply Chain Dive. (n.d.). Supply Chain Disruption. https://www.supplychaindive.com/topic/supply-chain-disruption/

b. McKinsey & Company. (2020). Building Resilient Supply Chains for a Post-COVID World. https://www.mckinsey.com/business-functions/operations/our-insights/building-resilient-supply-chains-for-a-post-covid-world